Considering the upcoming deadline for the 40 CFR 63 Subpart ZZZZ National Emission Standard for Hazardous Air Pollutants for Reciprocating Internal Combustion Engines (the “RICE MACT”), we thought this blog post courtesy of Trinity Consultants was appropriate...

Under the 40 CFR 63 Subpart ZZZZ National Emission Standard for Hazardous Air Pollutants for Reciprocating Internal Combustion Engines (the “RICE MACT”), the April 17th deadline is fast approaching for initial performance testing, or catalyst activity testing, as applicable, for two broad categories of engines with emissions standards: (1) existing SI RICE between 100 and 500 hp at major sources, and, (2) existing 4S SI RICE greater than 500 hp at non-remote area sources. To comply with the RICE MACT emissions standards, EPA assumes that the majority of these engines will need catalytic control, i.e., oxidation catalyst for the lean burn engines and three-way / non-selective catalyst for the rich burn engines. For any engine controlled by catalyst and subject to initial performance testing, the RICE MACT requires ongoing monitoring of parameters established during the testing. This monitoring must be completed according to a site-specific monitoring plan, and this plan should be in place by the date of the initial performance test, which, for the engine categories mentioned above, is just around the corner. Along with the 60-day notice and other items on your performance test to-do list, plan to carve out some time for developing your monitoring plan(s). Some details of what goes into the required monitoring plan are discussed below.

To read the rest of the post, check out Trinity's complete blog post clicking here. To learn about how Testo can help you with the upcoming RICE MACT regulations, check out testo350.com.

Friday, April 4, 2014

Thursday, March 27, 2014

Sensor zeroing for the testo 350 emission analyzer

Recently RAECO did a great blog post about sensor zeroing for the testo 350 portable emission analyzer...

Before we send any instrument to a customer, our technical team makes sure the unit is in good working order, runs a calibration, and checks all the parts.

Recently, one of our technicians experienced a small issue with a testo 350 combustion analyzer. He powered up the unit and it started going through its standard tests. Everything was going fine, and then he got the error code: O2 Sensor – Zeroing. He turned the device off and back on again (an IT-guy trick), but the error stayed. The sensor wasn’t old, so it should have worked fine.

So how did he solve the issue?

The ultimate solution is to replace the sensor. But first, knowing the sensor was still fairly new, he tried another trick that our IT guy refers to as “jiggle the cords”. By that, he means to unplug the parts and plug them back in again, to make sure all the connections are good. In this case, it meant re-seating the sensor to make sure it was connecting properly.

Want to read the rest of the post? Check out RAECO's blog by clicking here.

Before we send any instrument to a customer, our technical team makes sure the unit is in good working order, runs a calibration, and checks all the parts.

Recently, one of our technicians experienced a small issue with a testo 350 combustion analyzer. He powered up the unit and it started going through its standard tests. Everything was going fine, and then he got the error code: O2 Sensor – Zeroing. He turned the device off and back on again (an IT-guy trick), but the error stayed. The sensor wasn’t old, so it should have worked fine.

So how did he solve the issue?

The ultimate solution is to replace the sensor. But first, knowing the sensor was still fairly new, he tried another trick that our IT guy refers to as “jiggle the cords”. By that, he means to unplug the parts and plug them back in again, to make sure all the connections are good. In this case, it meant re-seating the sensor to make sure it was connecting properly.

Want to read the rest of the post? Check out RAECO's blog by clicking here.

Wednesday, March 12, 2014

Exhaust Gas Testing in Mines

The Federal Mine Safety and Health Act

The Federal Mine Safety and Health Act (Mine Act) requires that the U.S. Department of Labor's (DOL) Mine Safety and Health Administration (MSHA) inspect all mines each year to ensure safe and healthy work environments for miners. Section 75.1914(g) requires mine operators to develop and implement written standard operating procedures for weekly testing and evaluation of undiluted exhaust emissions from permissible and heavy-duty diesel-powered equipment in use underground.

Increased Nitrogen Dioxide (NO2) Emissions in Coal Mines

Some underground coal mine operators have experienced excessive Nitrogen Dioxide (NO2) emissions on several heavy-duty diesel powered locomotives and light-duty service machines while trying to meet the requirements for diesel particulates for the MSHA Health Hazard Alert. Symptoms of overexposure to NO2 include irritation to the eyes, nose and throat, cough, chronic bronchitis, breathing difficulty, chest pain, pulmonary edema, and rapid heartbeat.

Exhaust Gas Monitoring: 30 CFR § 70.1900

As required by 30 CFR § 70.1900 for Exhaust Gas Monitoring, both carbon monoxide and nitrogen dioxide are measured.

How Testo Can Help...

Testo has a complete line of products to assist in testing the exhaust gas of each diesel powered unit. The testo 340 four-gas analyzer is perfect identifying concentrations of O2, CO, NO, and N2SO. Your maintenance team can better evaluate the source of high concentrations. The testo 340 helps you understand the combustion characteristics of your engines so they can be tuned for higher performance and minimal pollutants. The testo 340 provides the following benefits...

Portable Emission Analysis

For compliance level documentation and reporting, the testo 350 portable emission analyzer with easyEmission software may be the right solution for you.

To learn more about the testo 340 four-gas analyzer or the testo 350 portable emission analyzer for exhaust gas testing in mines, email us at info@testo.com or call toll-free 800-227-0729.

The Federal Mine Safety and Health Act (Mine Act) requires that the U.S. Department of Labor's (DOL) Mine Safety and Health Administration (MSHA) inspect all mines each year to ensure safe and healthy work environments for miners. Section 75.1914(g) requires mine operators to develop and implement written standard operating procedures for weekly testing and evaluation of undiluted exhaust emissions from permissible and heavy-duty diesel-powered equipment in use underground.

Increased Nitrogen Dioxide (NO2) Emissions in Coal Mines

Some underground coal mine operators have experienced excessive Nitrogen Dioxide (NO2) emissions on several heavy-duty diesel powered locomotives and light-duty service machines while trying to meet the requirements for diesel particulates for the MSHA Health Hazard Alert. Symptoms of overexposure to NO2 include irritation to the eyes, nose and throat, cough, chronic bronchitis, breathing difficulty, chest pain, pulmonary edema, and rapid heartbeat.

Exhaust Gas Monitoring: 30 CFR § 70.1900

As required by 30 CFR § 70.1900 for Exhaust Gas Monitoring, both carbon monoxide and nitrogen dioxide are measured.

How Testo Can Help...

Testo has a complete line of products to assist in testing the exhaust gas of each diesel powered unit. The testo 340 four-gas analyzer is perfect identifying concentrations of O2, CO, NO, and N2SO. Your maintenance team can better evaluate the source of high concentrations. The testo 340 helps you understand the combustion characteristics of your engines so they can be tuned for higher performance and minimal pollutants. The testo 340 provides the following benefits...

- Direct reading for O2 and NO2

- Probes with sintered filters for diesel exhaust

- easyEmission software for documentation and reporting

- Rugged for tough mining environments

Portable Emission Analysis

For compliance level documentation and reporting, the testo 350 portable emission analyzer with easyEmission software may be the right solution for you.

To learn more about the testo 340 four-gas analyzer or the testo 350 portable emission analyzer for exhaust gas testing in mines, email us at info@testo.com or call toll-free 800-227-0729.

Friday, September 27, 2013

Testo and Veto are a winning team!

Testo and Veto Pro Pac have teamed up to offer technicians a premium offer at a great value. When a technician purchases any Testo combustion or emission analyzer kit, they will receive a Veto tool bag free!

testo 350 Portable Emission Analyzer

The testo 350 portable emission analyzer raises the bar in testing serviceability. Its design allows for routine service and "plug and play" convenience – no tools needed. Simply click out the sensor, or chiller filter, or pump – it's that simple.

The testo 350 portable emission analyzer raises the bar in testing serviceability. Its design allows for routine service and "plug and play" convenience – no tools needed. Simply click out the sensor, or chiller filter, or pump – it's that simple.Other features include:

• Easy-access service opening

• Thermally-separated sensor chamber

• Plug and play "smart sensors" for easy field replacement

• Automatically monitored condensate trap with CO2 upgrade

• Cooling loop designed to isolate electronics and sensors from harsh ambient conditions

• Automatic flow-controlled sampling pump so a constant sample flow is maintained

testo 340 4-Gas Combustion Analyzer

The ultimate instrument in portable combustion tuningOptimizing combustion, increasing efficiency and minimizing fuel use are necessary to compete in today's market. The testo 340 four gas combustion analyzer provides the information to understand your process, enabling you to make informed combustion decisions. With field-replaceable pre-calibrated sensors, you have zero down-time and keep testing. It is the ideal tool to confirm proper set-up or identify emission problems.

Buy a testo 340 or a testo 350 emission analyzer kit and get a Veto Pro Pac TECH-LC bag free!

The TECH-LC bag has been made to accommodate a technician's tools and work routines. It sports 53 pockets and eight small neoprene pockets, providing ample room for everything a technician needs at the job site.To learn more about this great offer check out the fall promotion page or call toll-free 800-227-0729.

Wednesday, September 4, 2013

Are you Ready for the new Complex engine testing regulations from the EPA?

As the new federal guidelines for testing stationary Reciprocating Internal Combustion Engines (RICE) make their way into the field, they generate questions about how to comply with the many different scenarios. The National Emission engine testingEmission Standards for Hazardous Air Pollutions (NESHAP) 40 CFR subpart ZZZZ (aka "quad Z") addresses one type of engine and different types of testing criteria. The New Source Performance Standards (NSPS) subpart JJJJ (aka "quad J") addresses still another set of engines and testing criteria. Needless to say, navigating through the EPA requirements, and realizing that every engine and engine site is different, results in a complex testing determination. To further compound the complexity, as of this writing EPA is reconsidering the requirements of some diesel and emergency engines. For the latest information on regulations, feel free to check out the emission testing links page on testo350.com.

As the new federal guidelines for testing stationary Reciprocating Internal Combustion Engines (RICE) make their way into the field, they generate questions about how to comply with the many different scenarios. The National Emission engine testingEmission Standards for Hazardous Air Pollutions (NESHAP) 40 CFR subpart ZZZZ (aka "quad Z") addresses one type of engine and different types of testing criteria. The New Source Performance Standards (NSPS) subpart JJJJ (aka "quad J") addresses still another set of engines and testing criteria. Needless to say, navigating through the EPA requirements, and realizing that every engine and engine site is different, results in a complex testing determination. To further compound the complexity, as of this writing EPA is reconsidering the requirements of some diesel and emergency engines. For the latest information on regulations, feel free to check out the emission testing links page on testo350.com.In both the quad Z and J standards, portable electrochemical (EC) emission analyzers are accepted for testing under each regulation. Since the late 1990s, portable EC analyzers have demonstrated that both high accuracy and low cost are achievable. As portable analyzers continue to improve, Testo has been the leader in providing innovative field testing capability and performance.

New Testo analyzer capability

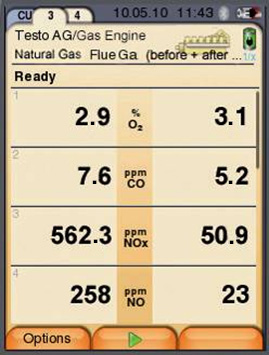

Specific to performance testing of catalysts (under the quad Z) Testo has developed an innovative simultaneous testing solution. The regulation requires pre- and post-catalyst testing of the exhaust gas on a simultaneous basis. The typical solution in the past was to use two separate trucks with separate analyzers. Separate data acquisitions systems were also used to join the data for review and reporting.

Innovative multi-unit simultaneous testing

The testo 350 portable emission analyzer has unique features that greatly reduce the hardware and software needed and make data logging and review easier. Two analyzers can be linked to display the catalyst measurements. It's simple and the cost for this system is also substantially lower than the traditional trailer mounted testing rigs.

The testo 350 system is unique in form and function. It starts by connecting two probes and analyzer

boxes to the exhaust stack. Each analyzer is specifically configured for the different gas conditions found in pre- and post-catalyst exhaust gas. Then both analyzers are connected to the handheld control unit and the magic begins - the high def. graphic display in the control unit shows the side-by-side measurements. Communication through Testo’s data “BUS” system makes it all possible.

boxes to the exhaust stack. Each analyzer is specifically configured for the different gas conditions found in pre- and post-catalyst exhaust gas. Then both analyzers are connected to the handheld control unit and the magic begins - the high def. graphic display in the control unit shows the side-by-side measurements. Communication through Testo’s data “BUS” system makes it all possible.Data collection and interpretation is much easier when you know the actual pre- and post-catalyst measurement in real time. Managing data is the next critical requirement and Testo takes this capability further in its easyEmission software. Not only can the simultaneous measurement be displayed in a variety of formats with simple two analyzer operation, easyEmission can display measurements of up to 16 analyzer boxes for the ultimate in simultaneous, multi-unit testing.

The testo 350 portable emission analyzer provides extensive testing capabilities unmatched in the industry. Contact Testo for a demonstration of this multi-unit testing and let us show you how easy emission testing can be.

Subscribe to:

Comments (Atom)